Menu

Menu

Manufacturers managing numerous SKUs across complex product lines—especially in hardware accessories—often face challenges around inconsistent quality, unreliable timelines, and volatile costs.

In this client's scenario, the primary challenges included:

“I think there are three primary challenges that most clients come to us with: quality, reliability, and pricing consistency. If your sell cost is set, you need to know your packaging cost won't fluctuate unpredictably. On reliability, if you can't get your product on time—it's something a supply chain or procurement professional never wants to deal with. And quality problems can also damage brand perception, distributor relationships and render goods unsellable.”- JJ Giese, VP of Client Success at Thysse

JJ emphasizes that “the first key in any challenge is just understanding really what the problem is. Sometimes what that problem is doesn't actually look the same on the surface, so digging in as a partner to understand the real challenge—and if there are multiple challenges, what their hierarchy is—is crucial.”

The client's three-bid approach, designed for cost savings, inadvertently created operational burdens:

“A thing that often gets overlooked is how much time and energy goes into a three-bid process. Your team works with multiple providers, sending out information, waiting for responses. It’s so much more efficient if you lean into a partner, leveraging the body of work to drive efficiencies, build good communication, understanding, and trust—saving significant time, effort and ultimately, cost,” JJ clarifies.

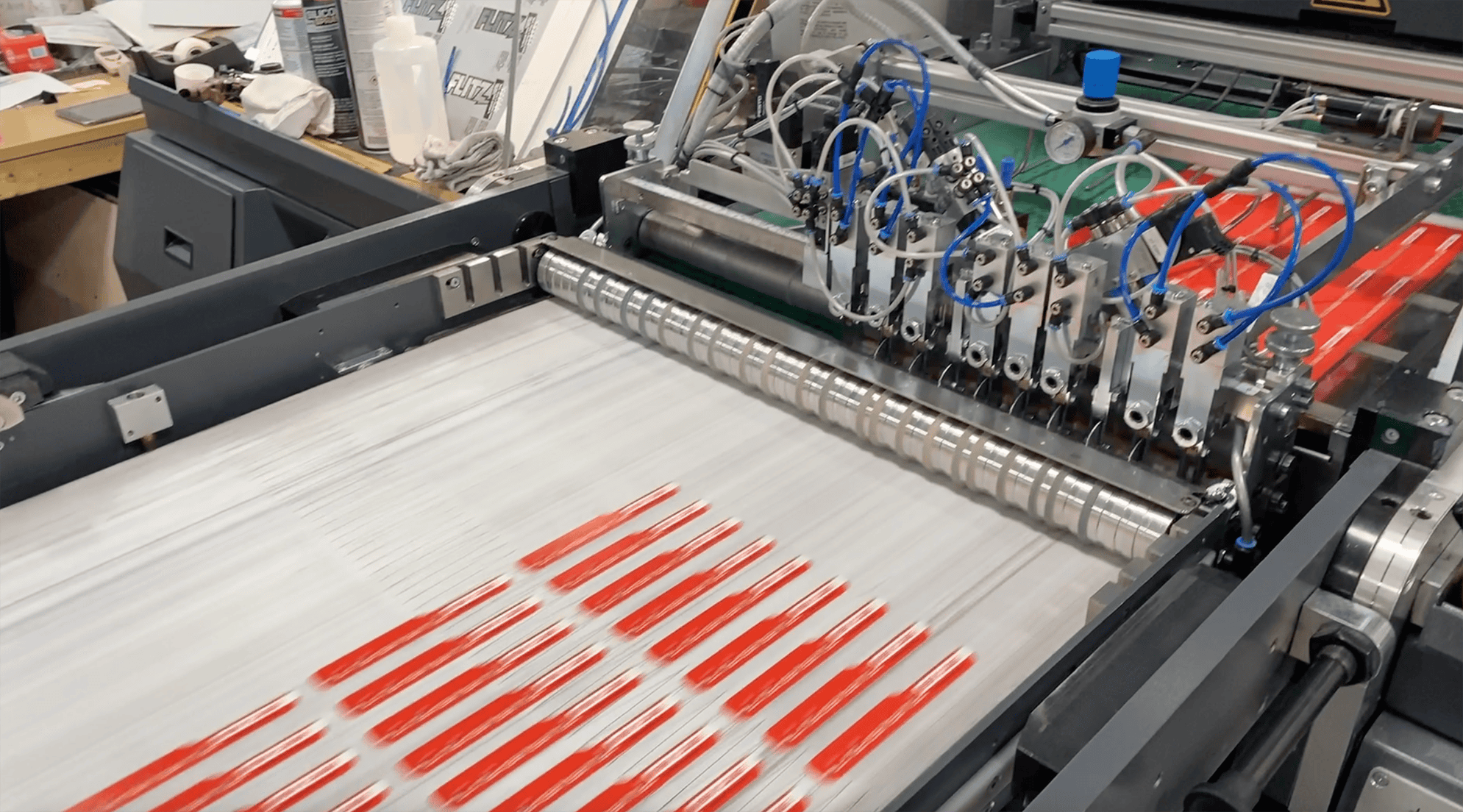

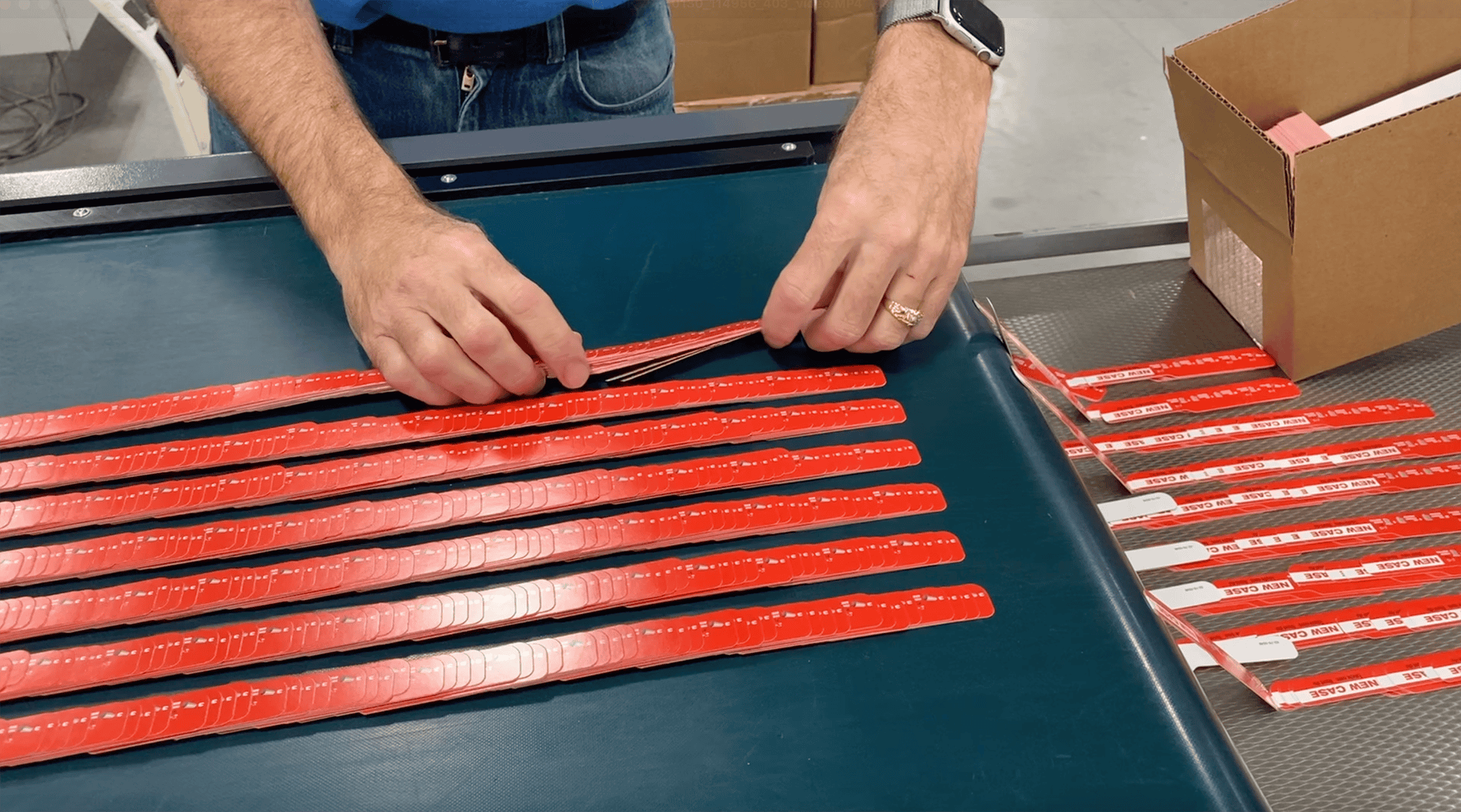

Thysse recommended transitioning away from the three-bid model toward a committed partnership for several reasons. The commitment enabled us to leverage better material costs from our suppliers which helped achieve better cost stability and cost efficiency. It also enabled us to invest in the partnership by:

JJ explains that “by starting a monthly order at the same time each month, we can prepare our materials, align supply chains with our providers, and minimize stressful last-minute fire drills. It keeps things running smoothly on both ends.”

The strategic partnership significantly improved the client's supply chain:

“Our customer service stands out because our account managers and project managers all have over 20 years of experience. They understand our equipment, strengths, and limitations. If something doesn’t meet expectations, we'll call it out right away. We strive for every piece to meet or exceed those expectations—often correcting it before our client is even aware.”- JJ Giese, VP of Client Success at Thysse

Transitioning from transactional vendor relationships to strategic partnerships unlocks value beyond unit costs:

“Not every manufacturer has a big in-house packaging team, and not everyone wants to feel like a small fish working with a giant supplier. Thysse is big enough to be capable and efficient, yet small enough to be agile and flexible. Sometimes it’s nice to be a big fish in a medium pond. Partnerships offer strategic alignment and benefits that traditional vendor relationships simply can’t match.”- JJ Giese, VP of Client Success at Thysse

While the benefits of stabilized pricing, a streamlined bidding process, and operational consistency were quickly realized, those were just the foundational changes.

Time, great communication and the stability the partnership created fostered an environment where both teams were able to work together and invest in each other. Month-in month-out, small improvements refined the system, and over time they add up. Now, with custom software solutions, report automations, supplier agreements and the body of experience behind both teams, quality and schedule problems are simply not part of the equation.

JJ concludes "it’s gratifying to develop partnerships and systems that work well. It’s good for us, and our clients. Ultimately, it isn’t about print. It’s about building systems that work for our clients. Whether in packaging, retail graphics, commercial print or mail–it’s about systems, communication, logistics, and helping the teams within organizations reach their goals. We’re not just here for a job. We’re here for the long haul, offering ourselves as an extension of teams–offering the unique abilities and capabilities we have to unlock value beyond just ‘making and shipping products’. That’s not always the case with vendor/client relationships, but it’s definitely how every member of Team Thysse approaches it.”

Looking for a Better [Packaging] Partner?

Visit Thysse.com to learn more, or contact JJ directly at jj@thysse.com.