Menu

Menu

The widespread use of plastics in virtually every industry comes from its incredible versatility, cost-efficiency and engineerable physical properties. Within print and signage applications, the number of uses and options is almost overwhelming. Before Steve breaks it down for us, let’s take a brief aside to address the pros and cons of plastic usage, in general.

Plastics have often been criticized for their environmental impact, and in many cases, rightfully so. Plastic isn’t always the best choice, but this may come as a surprise: there are actually sustainability advantages to plastic substrates in some cases!

Certain types are recyclable or biodegradable, but combining different plastics and non-plastic substrates in signage, packaging and product labeling can create sorting problems that prevent them from being recycled.

Thoughtfully selecting the right combinations of plastic project elements, from vessels and labels to fasteners, substrates and inks can eliminate the need for sorting and improve the likelihood and efficiency of recycling. Post-use awareness and consideration is an increasingly prevalent and welcome step in substrate selection within the print industry. Marketing and supply chain-decision makers often introduce and lead these efforts, but sourcing and actually manufacturing/printing with them takes a flexible partner. Thysse is proud to be that type of partner.

Without further ado, here’s a breakdown of the different plastics Thysse uses and how they’re applied across industries.

At Thysse, we work with several plastic-based materials, each suited for specific applications and environments. Let’s dive into the most commonly used ones:

Coroplast is corrugated plastic, similar in structure to corrugated cardboard but made from waterproof polypropylene. It’s lightweight, inexpensive, and commonly used for yard signs, election signage, and temporary event displays. It comes in different colors, too, so vibrant messaging can be achieved with less ink coverage.

Coroplast is the industry standard for short-term outdoor messaging. If you’ve ever seen a real estate sign, campaign sign, or graduation yard sign, it was likely printed on coroplast.

For higher-end, semi-rigid signage, PETG and acrylic offer a polished, professional look. These plastics are commonly used in corporate environments, retail displays, and interior signage.

PETG (Polyethylene Terephthalate Glycol) – A clear, impact-resistant plastic that is flexible and cost-effective. It’s recyclable and is used for:

Acrylic (Plexiglass-like material) – A more rigid, high-end alternative that can be cut into shapes, engraved, or layered for a dimensional look. It’s also recyclable and is used for:

Acrylic provides a sleek, modern finish and is available in various colors and transparencies, making it a popular choice for high-end branding applications, especially within lighted displays and signage. The edges of acrylics can also be routed or rounded over if desired.

Styrene is a thin, flexible plastic used frequently for indoor retail signage, shelf talkers, and promotional displays. Styrene substrates are technically recyclable, but the process is more complex. Your local blue-bin recycling providers may not accept styrene products, but if you have sufficient quantities locating and delivering post-use styrene materials to a recycling facility that does accept them is an option. Organizations like the Association of Plastics Recyclers (APR) exist to help make these connections, so there certainly are options and resources available.

Many national retailers use styrene signage in-store because it’s cost-effective, visually appealing, and easy to swap out during promotions.

Expanded PVC (EPVC), known by brand names like Sintra or Komatex, is a rigid, smooth-surfaced plastic foam. It’s commonly used for high-end indoor signage, menu boards, and dimensional displays. Like styrene products, it can be recycled but may require additional steps to locate a provider that accepts it.

EPVC is heat-formable and routable/millable, so it can be printed flat and then shaped or folded to finished form. Routing angled channels into EPVC enables it to fold on those seams to create 3D shapes without visible edge seams.

EPVC is a great choice for businesses needing durable indoor signage that’s heavier-duty than styrene but lighter than acrylic.

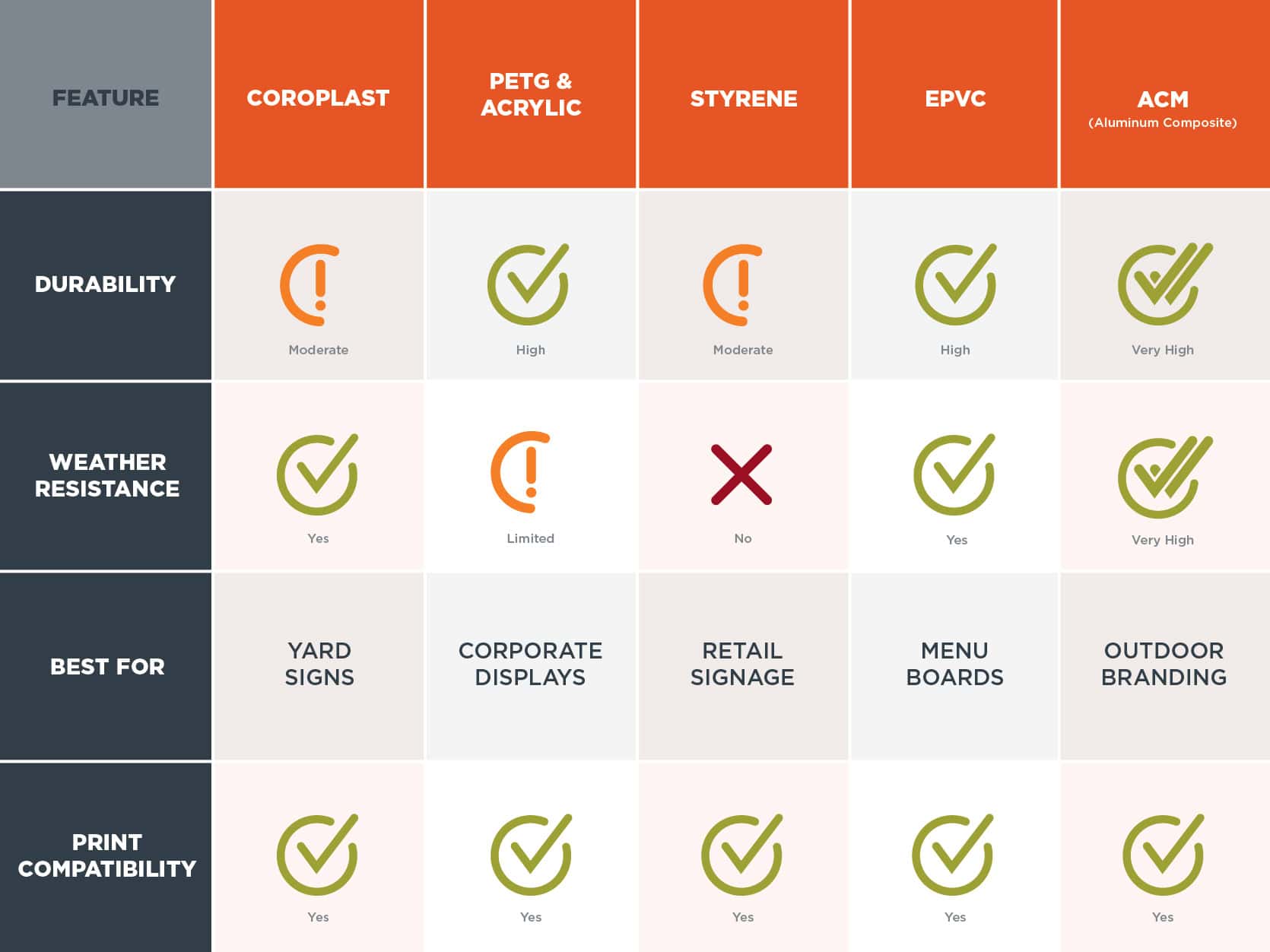

When selecting a substrate, it’s important to compare plastic materials with other common signage options:

For businesses looking to balance cost, durability, and aesthetic appeal, plastic substrates offer a range of solutions that can be tailored for different applications. Whether it’s a budget-friendly yard sign, an elegant acrylic lobby display, or a durable EPVC menu board, plastics provide versatility without sacrificing quality.

At Thysse, we work with clients to choose the right plastic material based on their project needs, location, and budget—ensuring the result is not only effective but also long-lasting.

If you need custom plastic-based signage, Thysse has the expertise, technology, and materials to bring your vision to life. Whether it’s temporary promotional signage or a premium branded display, we’ll help you find the perfect solution.

Have questions? Our experts are here to help! Reach out today or explore our growing library of resources.